English

English

English

English

PVC and Silicone Material

PVC Material

The coating PVC material is specially formulated for outdoor harsh environment, especially for protecting the light from UV, high temperature, dirt and corrosion, thus ensuring consistent lumen output to a large extent and long lifespan.

Silicone Material

Regular silicone material is with static electricity itself, so dust accmulate gradually on the light surface after long time use, which will affect the light output and difficult for clearance, especially when the light installed on building.

To solve this problem, we introduce another production process after extrusion molding, which creating a smooth coating on the light surface that isolate the light from dust, thus ensuring consistent lumen output to a large extent and simplify necessary cleaning.

Unique Sulphation Resistance Design

Traditional PVC strip has potential risk of sulphation by material contained sulphur. To solve this problem, we develop a special sulphur-free material coating on the surface of LED board, which totally isolate LED from PVC material, thus ensuring the whole light stability and realize long lifespan.

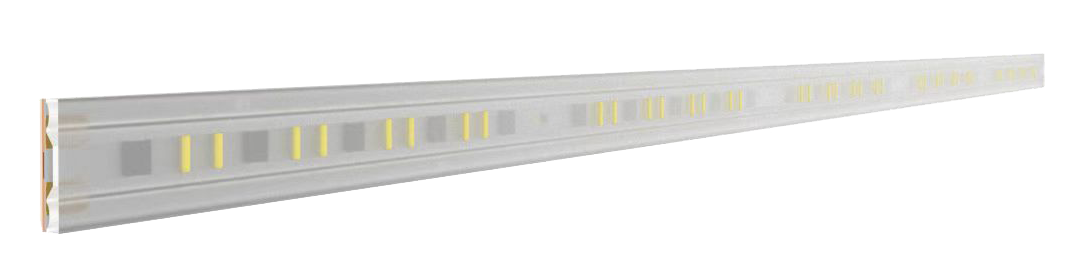

Excellent Optic Design

Normal PVC neon light on market adopt two-color coextrusion technology. That means the light guide layer share the same translucent color with light surface, which will lead to high power consumption but low light output.

We improve the technology to three-color coextrusion, requiring demandingly for extrusion technique, but exporting maximum brightness by high transparency light guide layer, which help the light realize low power consumption but high ligh output.

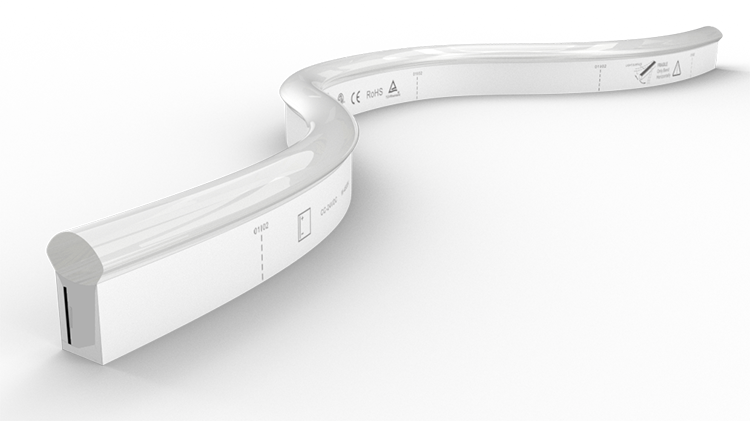

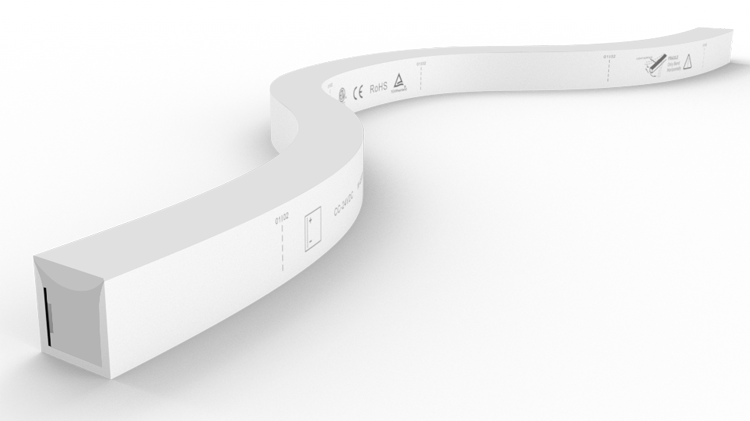

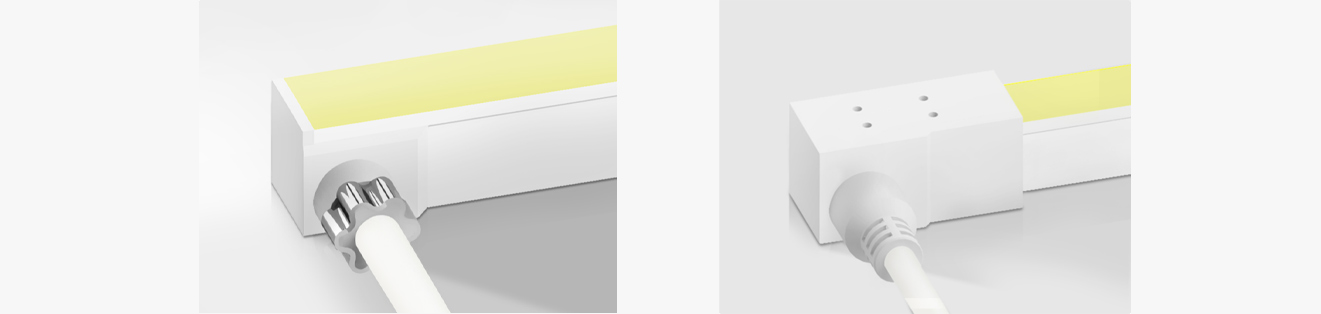

Injection-molding Connector

Traditional neon light often adopt DIY connectors, the shortcoming is though some kind of DIY connectors can theoretically reach IP65, IP67 or IP68, but on-site installation often fails due to nonstandard operation. Besides, DIY connectors often has bigger size than light, which is less felxible for mounting installation.

Injection molding connector is pre-made in factory by injection maching. The advantage is that the injected connector totally integrate with the surface of light, which realize true IP67 or IP68 protecton.

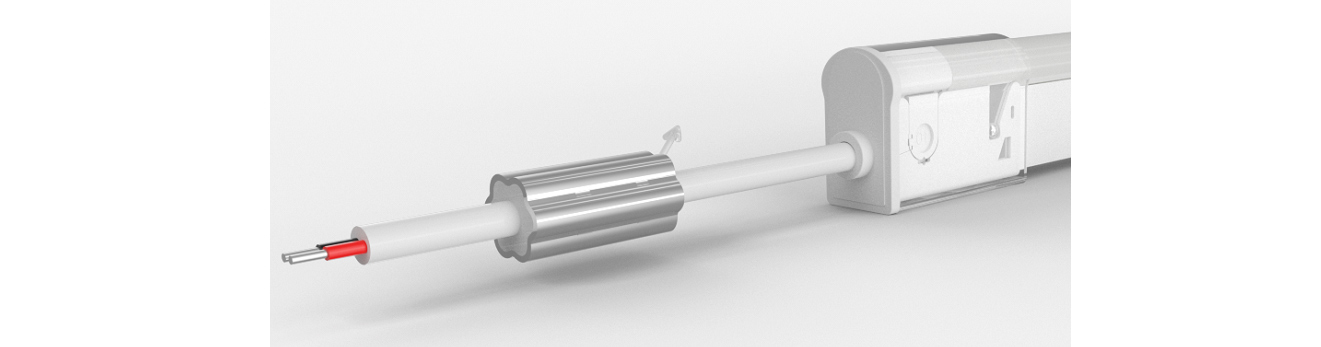

Waterproof Interrupter

For outdoor bareware products, water and moisture often slowly penetrate the light from the conducting wire which lead to short circuit damage of light.

The core function of this waterproof interrupter is to block water and moisture penetrating into light, to guarrantee the whole light's waterproof effect as long as this interrupter is well kept on cable.

Electrical and Physical Related Materials

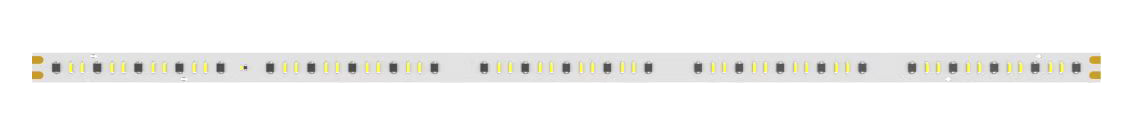

Light Source

For standard products, we use Epistar SMD LED, and strictly keep one bin only and 3 Step MacAdam from LED supplier.

Cree/Nichia/Philips chips are optional for static colors. Besides, all brackets used inside LED are customly made for demanding hardness, to guarantee superb performance during bending.

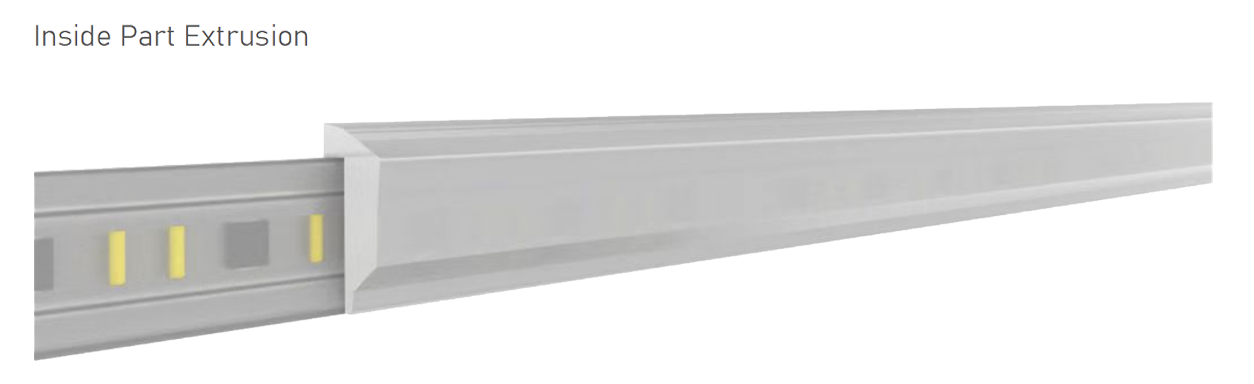

FPCB

4OZ (cooper thickness) FPC with calendered cooper adopted, which optimize heat dissipation to housing and minimize voltage drop, thus realize max. running length up to 30m by single end feed.

Functioning together with the bottom protective rigid plate, the structure immensely improve the light's mechanical strength against bending.

Electronic Component

For constant current versions, electronic components costs high as we use high quality electronic components not only for most stable performance, but also physically strong for bending

Quick Links

E-mail: senbe007@senbelighting.com

Tel.: +86 20 3913 7589

Mob.: +86 139 2877 1493

Add.: Building B6, Huachuang Industrial Park, Shiji Town, Panyu District, Guangzhou, 511450